Integrated medium temperature, medium pressure and sub high pressure temperature and pressure reducing device (wy01, wy02, wy05 / 06, wy09 / 10 series)

1. Structural characteristics

WY series of temperature and pressure reducing device is a temperature and pressure reducing device designed by our company with many years of design and manufacturing experience, absorbing foreign advanced product structure and technical optimization.

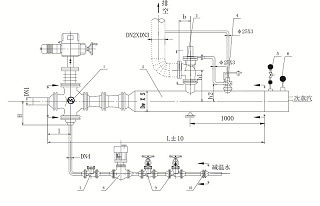

The desuperheating and pressure reducing device is composed of desuperheating and pressure reducing valve, throttle orifice, water supply regulating valve, safety valve, throttle valve, stop valve, check valve, steam pipe, water supply pipe, flange, fastener, etc. its main features are as follows:

1. With the structure of temperature and pressure reducing valve, the steam temperature and pressure reduction are carried out in the same valve, which greatly shortens the length of the whole unit, reduces the occupied area and reduces the project investment.

2. It adopts the structure of straight stroke double seat cage type temperature and pressure reducing valve. The valve is equipped with throttle net cover to enhance the atomization effect of desuperheating water, protect the valve seat and valve body, extend the service life of the valve, and reduce the noise of the device. The double seat valve has the advantages of small imbalance force, wide adjustment range and stable operation, so it will never be stuck. The sealing surface of the sub high pressure desuperheating and reducing valve is overlaid with cobalt based ercrmn-c-15, which is resistant to high temperature and scour; the valve seat and disc are single matched with adhesive wear, which has good sealing performance and overcomes the defect of large leakage of the double seat valve, and the applicable temperature is 510 ℃.

3. A unique nozzle is set in the desuperheating and reducing valve. The desuperheating water passes through the longer water chamber set in the valve core, making full use of the higher temperature of the primary steam to fully preheat. Part of the desuperheating water has been basically atomized before the spray of the annular nozzle, and the non atomized desuperheating water drops are further collided and atomized through the throttling hole cover at about 400 ℃, so the atomization effect is excellent.

4. Another important index of desuperheating water atomization is that the minimum steam flow rate at the spray point is ≥ 8m / s, while the steam flow rate between the valve disc and the valve seat in the desuperheating and reducing valve (i.e. the spray point of desuperheating water) is basically greater than 180m / s, which is equivalent to the flow rate required by the venturi desuperheater, and the atomization effect is excellent.

5. When the load of the desuperheater and pressure reducer changes greatly (10-110% q), especially when the load is small, the desuperheating water is preheated and atomized on the premise of making full use of the thermal energy and kinetic energy of the primary steam parameters, which makes up for the decrease of the desuperheating water flow speed and ensures that the desuperheating water can be fully and rapidly atomized in the atomizing section.

6. Noise reduction. On the one hand, the throttle cover and the throttle plate behind the temperature and pressure reducing valve play the role of pressure reducing atomization, and the main role is to reduce the noise in the system. The main principle is its small hole silencing.

7. Flow characteristics of temperature and pressure reducing valve: linear, leakage level: level III.

8. The temperature feed water regulating system adopts direct stroke single seat regulating valve (or V-type regulating valve) + throttling device, which not only reduces the leakage of the valve, but also can reasonably distribute the pressure difference on the feed water system; the same caliber, different flow coefficient CV values can be selected, which greatly improves the sensitivity and accuracy of the temperature regulating system.

9. Electric temperature and pressure reducing valve and electric water supply regulating valve are equipped with direct stroke electric actuator, which eliminates the traditional lever hinge mechanism, reduces the empty stroke link, and further improves the sensitivity and accuracy of the regulating system.

2. Model selection description of medium temperature and medium pressure desuperheating and reducing device (Table 1)

In the selection table of temperature and pressure reducing device, for the commonly used new steam parameters P1 and T1 of medium and low pressure boilers to the outlet steam parameters P2 = 1.4 ~ 0.1MPa, T2 = 400 ~ 130 ℃, and the flow Q = 2 ~ 120t / h, the series specification and code of the device required by the corresponding parameters are given one by one.

Note: ① the parameters listed in Table 1 are conventional parameters. If the corresponding series specification code cannot be found in the table for special parameters, contact the technical department of the company;

② when preparing this table, the parameters of desuperheating water supply are calculated with pressure Pb = 0.6p1 + 1.0MPa and temperature TB = 104 ℃.

3. Scope of supply

The scope of supply of temperature and pressure reducing device is within the mark, mainly including:

(1) pressure reducing system: temperature and pressure reducing valve, throttle orifice, etc;

(2) desuperheating system: feed water regulating valve, throttle valve, etc;

(3) safety system: safety valve, check valve, etc;

(4) pipeline system: steam pipe, transition pipe, desuperheating pipe, etc;

(5) supporting accessories: stop valve, bimetal thermometer and connecting pipe, pressure gauge and three-way valve, bend, joint, flange, gasket, bolt, nut, washer, etc.

4. Type selection of medium temperature, medium pressure, temperature and pressure reducing device

Table 1

|

Flow |

Secondary steam parameters |

Primary steam parametersP1(MPa)、T1(℃) |

||||||||||||||||||||||||

|

PressureP2 |

TemperatureT2 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

|||||||||||||

|

1.3 |

300 |

1.3 |

350 |

2.5 |

375 |

2.5 |

400 |

3.5 |

435 |

3.9 |

450 |

|||||||||||||||

|

2 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|||||||||||||||||||||||||

|

0.2 |

150 |

WY05-005MX |

WY05-005MX |

WY05-005MX |

WY05-005MX |

|||||||||||||||||||||

|

0.3 |

160 |

|||||||||||||||||||||||||

|

0.4 |

170 |

WY05-001MX |

WY05-001MX |

WY05-001MX |

WY05-001MX |

|

|

|||||||||||||||||||

|

0.6 |

190 |

WY05-001MX |

WY05-001MX |

|||||||||||||||||||||||

|

0.8 |

220 |

|||||||||||||||||||||||||

|

1.0 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

|

|

|||||||||||||||||||||||

|

5 |

0.05 |

130 |

WY01-014MX |

WY01-014MX |

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

WY01-002MX |

WY01-002MX |

|

|

|||||||||||||||||||||

|

0.2 |

150 |

WY01-002MX |

WY01-002MX |

|||||||||||||||||||||||

|

0.3 |

160 |

MY05-017MX |

MY05-017MX |

MY05-017MX |

MY05-017MX |

|||||||||||||||||||||

|

0.4 |

170 |

|||||||||||||||||||||||||

|

0.6 |

190 |

WY05-007MX |

WY05-007MX |

WY05-007MX |

WY05-007MX |

WY05-006MX |

WY05-006MX |

|||||||||||||||||||

|

0.8 |

220 |

WY05-004MX |

WY05-004MX |

WY05-004MX |

WY05-004MX |

WY05-005MX |

WY05-005MX |

|||||||||||||||||||

|

1.0 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

|

|

|||||||||||||||||||||||

|

10 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

WY01-033MX |

WY01-033MX |

|

|

|||||||||||||||||||||

|

0.2 |

150 |

WY01-015MX |

WY01-015MX |

WY01-015MX |

WY01-015MX |

|||||||||||||||||||||

|

0.3 |

160 |

WY01-003MX |

WY01-003MX |

WY01-003MX |

WY01-003MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-002MX |

WY01-002MX |

|||||||||||||||||||||||

|

0.5 |

180 |

|||||||||||||||||||||||||

|

0.6 |

190 |

|||||||||||||||||||||||||

|

0.7 |

220 |

WY05-018MX |

WY05-018MX |

WY05-018MX |

WY05-018MX |

WY05-017MX |

WY05-017MX |

|||||||||||||||||||

|

0.8 |

220 |

|||||||||||||||||||||||||

|

1.0 |

250 |

|

|

WY05-018MX |

WY05-018MX |

WY05-017MX |

WY05-017MX |

|||||||||||||||||||

|

1.3 |

300 |

|

|

WY05-007MX |

WY05-007MX |

|||||||||||||||||||||

|

1.4 |

350 |

|||||||||||||||||||||||||

|

15 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|||||||||||||||||||||||||

|

0.2 |

150 |

WY01-034MX |

WY01-034MX |

WY01-033MX |

WY01-033MX |

|

|

|||||||||||||||||||

|

0.3 |

160 |

WY01-016MX |

WY01-016MX |

WY01-015MX |

WY01-015MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-011MX |

WY01-011MX |

WY01-012MX |

WY01-012MX |

WY01-012MX |

WY01-012MX |

|||||||||||||||||||

|

0.7 |

220 |

WY01-004MX |

WY01-004MX |

WY01-003MX |

WY01-003MX |

WY01-003MX |

WY01-003MX |

|||||||||||||||||||

|

1.0 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

|

|

WY05-018MX |

WY05-018MX |

WY05-018MX |

WY05-018MX |

|||||||||||||||||||

|

1.4 |

350 |

|||||||||||||||||||||||||

|

20 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|

|

|

|

|||||||||||||||||||||

|

0.2 |

150 |

WY01-050MX |

WY01-050MX |

WY01-049MX |

WY01-054MX |

|||||||||||||||||||||

|

0.3 |

160 |

WY01-034MX |

WY01-034MX |

WY01-034MX |

WY01-024MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-035MX |

WY01-035MX |

WY01-023MX |

WY01-023MX |

|||||||||||||||||||||

|

0.5 |

180 |

WY01-017MX |

WY01-017MX |

WY01-016MX |

WY01-016MX |

WY01-023MX |

WY01-023MX |

|||||||||||||||||||

|

0.6 |

190 |

WY01-011MX |

WY01-011MX |

WY01-009MX |

WY01-009MX |

|||||||||||||||||||||

|

0.7 |

200 |

WY01-017MX |

WY01-017MX |

WY01-011MX |

WY01-011MX |

WY01-009MX |

WY01-009MX |

|||||||||||||||||||

|

0.8 |

220 |

WY01-004MX |

|

WY01-004MX |

WY01-004MX |

WY01-003MX |

WY01-003MX |

|||||||||||||||||||

|

1.0 |

250 |

|||||||||||||||||||||||||

|

1.1 |

300 |

|

|

|||||||||||||||||||||||

|

1.2 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

|||||||||||||||||||||||||

|

1.4 |

350 |

|||||||||||||||||||||||||

|

25 |

0.05 |

130 |

|

WY02-027MX |

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

WY02-017MX |

|

|

||||||||||||||||||||||

|

0.2 |

150 |

WY01-059MX |

WY01-064MX |

WY01-065MX |

WY01-065MX |

|||||||||||||||||||||

|

0.3 |

160 |

WY01-050MX |

WY01-053MX |

WY01-054MX |

WY01-054MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-035MX |

WY01-025MX |

WY01-024MX |

WY01-024MX |

WY01-023MX |

WY01-023MX |

|||||||||||||||||||

|

0.5 |

180 |

|||||||||||||||||||||||||

|

0.7 |

200 |

WY01-017MX |

WY01-017MX |

WY01-016MX |

WY01-019MX |

WY01-023MX |

WY01-023MX |

|||||||||||||||||||

|

1.0 |

250 |

WY01-011MX |

WY01-011MX |

WY01-009MX |

WY01-009MX |

|||||||||||||||||||||

|

1.2 |

250 |

|

|

WY01-004MX |

WY01-004MX |

WY01-009MX |

WY01-009MX |

|||||||||||||||||||

|

1.3 |

300 |

|

|

WY01-004MX |

WY01-004MX |

WY01-004MX |

WY01-003MX |

|||||||||||||||||||

|

30 |

0.05 |

130 |

WY02-027MX |

WY02-027MX |

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

WY02-017MX |

WY02-017MX |

|

|

|

|

|||||||||||||||||||

|

0.2 |

150 |

WY01-064MX |

WY01-064MX |

WY01-065MX |

WY01-065MX |

|

|

|||||||||||||||||||

|

0.3 |

160 |

WY01-059MX |

WY01-064MX |

WY01-065MX |

WY01-065MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-050MX |

WY01-053MX |

WY01-054MX |

WY01-054MX |

WY01-054MX |

WY01-054MX |

|||||||||||||||||||

|

0.5 |

180 |

WY01-035MX |

WY01-025MX |

WY01-024MX |

WY01-024MX |

WY01-024MX |

WY01-024MX |

|||||||||||||||||||

|

0.6 |

190 |

|||||||||||||||||||||||||

|

0.7 |

200 |

|||||||||||||||||||||||||

|

1.0 |

250 |

|

|

WY01-011MX |

WY01-011MX |

WY01-011MX |

WY01-019MX |

|||||||||||||||||||

|

1.3 |

300 |

WY01-019MX |

||||||||||||||||||||||||

|

35 |

0.05 |

130 |

WY01-026MX |

WY01-026MX |

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|||||||||||||||||||||||||

|

0.2 |

150 |

|

|

|||||||||||||||||||||||

|

0.3 |

160 |

WY01-063MX |

WY01-063MX |

WY01-065MX |

WY01-065MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-054MX |

WY01-054MX |

WY01-054MX |

WY01-065MX |

|||||||||||||||||||||

|

0.5 |

180 |

WY01-063MX |

WY01-063MX |

WY01-054MX |

WY01-054MX |

WY01-054MX |

WY01-065MX |

|||||||||||||||||||

|

0.7 |

200 |

|

WY01-026MX |

WY01-024MX |

WY01-024MX |

WY01-024MX |

WY01-024MX |

|||||||||||||||||||

|

1.0 |

250 |

|

WY01-017MX |

|

WY01-019MX |

WY01-019MX |

||||||||||||||||||||

|

1.3 |

300 |

|

WY02-017MX |

|||||||||||||||||||||||

|

40 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

WY02-026MX |

WY02-026MX |

|

|

|

|

|||||||||||||||||||

|

0.2 |

150 |

WY02-016MX |

WY02-016MX |

WY02-017MX |

WY02-017MX |

|||||||||||||||||||||

|

0.3 |

160 |

WY01-063MX |

WY01-063MX |

WY01-064MX |

WY01-064MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY01-065MX |

WY01-065MX |

|||||||||||||||||||||||

|

0.5 |

180 |

|||||||||||||||||||||||||

|

0.6 |

190 |

|

|

WY01-053MX |

WY01-053MX |

|

|

|||||||||||||||||||

|

0.7 |

200 |

WY01-025MX |

WY01-025MX |

|||||||||||||||||||||||

|

0.8 |

220 |

WY02-026MX |

WY01-024MX |

WY01-024MX |

||||||||||||||||||||||

|

1.0 |

250 |

|

||||||||||||||||||||||||

|

1.1 |

300 |

WY01-035MX |

WY01-035MX |

WY01-024MX |

WY01-024MX |

|||||||||||||||||||||

|

1.2 |

250 |

|

|

WY01-019MX |

WY01-019MX |

|||||||||||||||||||||

|

1.3 |

300 |

|

|

WY01-017MX |

WY01-017MX |

WY01-019MX |

WY01-019MX |

|||||||||||||||||||

|

1.4 |

350 |

WY01-016MX |

WY01-0167MX |

|||||||||||||||||||||||

|

60 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|||||||||||||||||||||||||

|

0.2 |

150 |

WY02-025MX |

WY02-025MX |

WY02-026MX |

WY02-026MX |

|||||||||||||||||||||

|

0.3 |

160 |

WY02-017MX |

WY02-017MX |

WY02-017MX |

WY02-017MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY02-017MX |

WY02-017MX |

WY02-016MX |

WY02-016MX |

WY02-017MX |

WY02-017MX |

|||||||||||||||||||

|

0.5 |

180 |

|

|

|

|

|

|

|||||||||||||||||||

|

0.6 |

190 |

WY01-63MX |

WY01-63MX |

WY01-064MX |

WY01-064MX |

|||||||||||||||||||||

|

0.7 |

200 |

|||||||||||||||||||||||||

|

0.8 |

220 |

WY01-062MX |

WY01-062MX |

WY01-63MX |

WY01-63MX |

WY01-064MX |

WY01-064MX |

|||||||||||||||||||

|

1.0 |

250 |

|

|

|

|

WY01-053MX |

WY01-053MX |

|||||||||||||||||||

|

1.2 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

|

|

|

|

WY01-040MX |

WY01-040MX |

|||||||||||||||||||

|

1.4 |

400 |

WY01039MX |

WY01-039MX |

|||||||||||||||||||||||

|

流 |

二次蒸汽参数 |

一次蒸汽参数P1、T1(℃) |

||||||||||||||||||||||||

|

压力P2 |

温度T2 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

P1 |

T1 |

|||||||||||||

|

1.3 |

300 |

1.3 |

350 |

2.5 |

375 |

2.5 |

400 |

3.5 |

435 |

3.9 |

450 |

|||||||||||||||

|

80 |

0.05 |

130 |

|

|

|

|

|

|

||||||||||||||||||

|

0.1 |

140 |

|

|

|

|

|

|

|||||||||||||||||||

|

0.2 |

150 |

|||||||||||||||||||||||||

|

0.3 |

160 |

WY02-025MX |

WY02-025MX |

WY02-026MX |

WY02-026MX |

|

|

|||||||||||||||||||

|

0.4 |

170 |

WY02-015MX |

WY02-015MX |

WY02-015MX |

WY02-016MX |

WY02-017MX |

WY02-017MX |

|||||||||||||||||||

|

0.5 |

180 |

|||||||||||||||||||||||||

|

0.6 |

190 |

|

|

|

|

|

|

|||||||||||||||||||

|

0.7 |

200 |

|||||||||||||||||||||||||

|

0.8 |

220 |

WY01-062MX |

WY01-062MX |

WY01-063MX |

WY01-063MX |

WY01-063MX |

WY01-064MX |

|||||||||||||||||||

|

1.0 |

250 |

|

|

|||||||||||||||||||||||

|

1.2 |

250 |

|||||||||||||||||||||||||

|

1.3 |

300 |

WY01-063MX |

WY01-063MX |

|||||||||||||||||||||||

|

1.4 |

350 |

WY01-060MX |

WY01-060MX |

WY01-063MX |

WY01-063MX |

|||||||||||||||||||||

|

120 |

0.3 |

160 |

|

|

|

|

|

|

||||||||||||||||||

|

0.4 |

170 |

|||||||||||||||||||||||||

|

0.5 |

180 |

|||||||||||||||||||||||||

|

0.6 |

190 |

WY02-024MX |

WY02-024MX |

WY02-025MX |

|

|

|

|||||||||||||||||||

|

0.7 |

200 |

WY02-024MX |

WY02-024MX |

WY02-025MX |

|

|

|

|||||||||||||||||||

|

0.8 |

220 |

WY02-014MX |

WY02-014MX |

WY02-015MX |

WY02-015MX |

|||||||||||||||||||||

|

1.0 |

250 |

WY02-014MX |

WY02-015MX |

WY02-015MX |

||||||||||||||||||||||

|

1.2 |

250 |

|

|

|

|

|

|

|||||||||||||||||||

|

1.3 |

300 |

|||||||||||||||||||||||||

|

1.4 |

350 |

|||||||||||||||||||||||||