Venturi desuperheater (W08 type)

1. Structural characteristics

1) the desuperheating atomization system is mainly composed of Venturi tube and flute nozzle. According to the change of secondary temperature, the electric water supply regulating valve regulates the water supply to achieve the purpose of temperature reduction.

2) the venturi tube structure has small pressure loss (< 0.05Mpa), low noise, no transmission parts and jamming; the flute nozzle can be disassembled at will for maintenance.

3) liner is added in the closing pipe to avoid thermal shock and protect the outer pipe.

4) the direct stroke single seat regulating valve (or V-type regulating valve) + throttling device is adopted in the desuperheating water supply regulating system, which not only reduces the leakage of the valve, but also reasonably distributes the pressure difference on the water supply system. With the same caliber, different CV values of flow coefficient can be selected, which greatly improves the adjustment sensitivity and accuracy of the temperature regulation system.

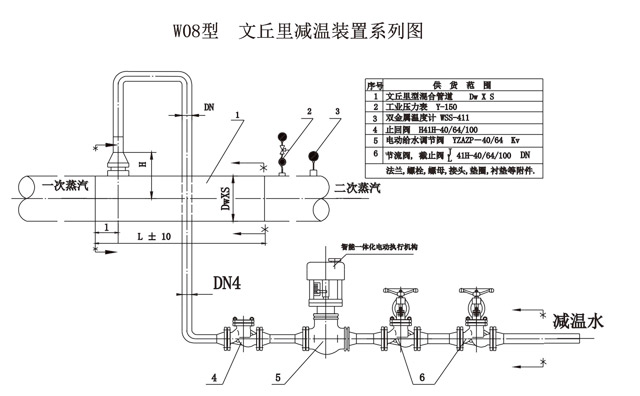

2. Series diagram:

3. Specification and dimension table of W08 Type DesuperheaterTable twenty

|

Nnumber |

General schedule |

Mixed pipeline |

Regulating valve |

l |

H |

L |

Device weight |

|

1 |

W08-001MX |

Φ57×4 |

20 |

100 |

127 |

1500 |

153 |

|

2 |

W08-002MX |

Φ89×4 |

100 |

143 |

1500 |

185 |

|

|

3 |

W08-003MX |

Φ108×4 |

100 |

152 |

1500 |

207 |

|

|

4 |

W08-004MX |

Φ133×4.5 |

100 |

165 |

1500 |

219 |

|

|

5 |

W08-005MX |

Φ159×6 |

144 |

185 |

1500 |

256 |

|

|

6 |

W08-006MX |

32 |

322 |

||||

|

7 |

W08-007MX |

Φ219×7 |

170 |

215 |

2000 |

368 |

|

|

8 |

W08-008MX |

20 |

302 |

||||

|

9 |

W08-009MX |

Φ273×10 |

185 |

242 |

2500 |

415 |

|

|

10 |

W08-010MX |

32 |

480 |

||||

|

11 |

W08-011MX |

Φ325×8 |

200 |

282 |

3000 |

499 |

|

|

12 |

W08-012MX |

20 |

268 |

427 |

|||

|

13 |

W08-013MX |

50 |

282 |

590 |

|||

|

14 |

W08-014MX |

Φ377×10 |

224 |

308 |

3500 |

725 |

|

|

15 |

W08-015MX |

20 |

294 |

562 |

|||

|

16 |

W08-016MX |

32 |

308 |

634 |

|||

|

17 |

W08-017MX |

Φ426×11 |

20 |

244 |

318 |

695 |

|

|

18 |

W08-018MX |

32 |

332 |

768 |

|||

|

19 |

W08-019MX |

50 |

860 |

||||

|

20 |

W08-020MX |

Φ530×10 |

450 |

650 |

1153 |

||

|

21 |

W08-021MX |

32 |

1062 |

||||

|

22 |

W08-022MX |

20 |

996 |

||||

|

23 |

W08-023MX |

Φ630×10 |

500 |

675 |

1349 |

||

|

24 |

W08-024MX |

32 |

1415 |

||||

|

25 |

W08-025MX |

50 |

1506 |

||||

|

26 |

W08-026MX |

Φ720×10 |

500 |

726 |

1728 |

||

|

27 |

W08-027MX |

32 |

1637 |

||||

|

28 |

W08-028MX |

20 |

1571 |

||||

|

29 |

W08-029MX |

Φ820×10 |

550 |

735 |

2112 |

||

|

30 |

W08-030MX |

32 |

2178 |

||||

|

31 |

W08-031MX |

50 |

2269 |

Screw nozzle desuperheater (type W12)

1. Structural characteristics

(1) the swirl structure is its design mechanism. The unique swirl structure can make the desuperheating water rotate at a high speed and get fine atomized water drops, which can effectively avoid the occurrence of drips;

(2) the atomization effect is good, the temperature reducing water generates hollow cones through the spiral nozzles, the spray area is annular, and the spray angle is

From 51 to 144 degrees, under the condition of large impact and pressure loading, it can also produce droplet size 0.1mm evenly distributed spray, which greatly improves the heat transfer area, reduces the atomization time and atomization section.

(3) the spiral nozzle is inlaid type, and each carefully designed and manufactured spiral nozzle is tested for flow coefficient before installation to ensure accurate flow control;

(4) there is no transmission element and jamming phenomenon in the spiral nozzle. The swirl structure has a large and smooth flow channel, eliminating the phenomenon of nozzle blockage.

2. Series diagram

3. Specification and size table of each series of W12 type spiral nozzle Desuperheater

Table twenty-one

|

Nnumber |

General schedule |

Mixed pipeline |

Regulating valve |

l |

H |

L |

Device weight |

|

1 |

W12-001MX |

Φ159×7 |

20 |

144 |

210 |

1500 |

143 |

|

2 |

W12-002MX |

32 |

158 |

||||

|

3 |

W12-003MX |

Φ219×9 |

20 |

170 |

260 |

1800 |

176 |

|

4 |

W12-004MX |

32 |

195 |

||||

|

5 |

W12-005MX |

Φ273×11 |

20 |

185 |

320 |

2000 |

230 |

|

6 |

W12-006MX |

32 |

245 |

||||

|

7 |

W12-007MX |

Φ325×8 |

20 |

200 |

340 340 |

2500 |

270 |

|

8 |

W12-008MX |

32 |

295 |

||||

|

9 |

W12-009MX |

Φ377×10 |

20 |

224 |

385 385 |

3000 |

315 |

|

10 |

W12-010MX |

32 |

328 |

||||

|

11 |

W12-011MX |

Φ426×11 |

20 |

244 |

420 |

3000 |

346 |

|

12 |

W12-012MX |

32 |

420 |

360 |

|||

|

13 |

W12-013MX |

50 |

420 |

385 |

(VII) adjustable screw nozzle desuperheating device (type w15)

1. Performance characteristics

(1) the adjustable spiral nozzle is to install a certain number of spiral nozzles on the basis of the adjustable nozzle, which is mainly used for the conditions of large steam flow and large load change;

(2) the actuator drives the valve disc to move up and down to change the number of nozzles put into operation, so as to control the flow of desuperheating water more accurately and ensure the flow rate of desuperheating water to be constant. It has a large adjustable ratio of 1:40, adjustable characteristics: straight line, equal percentage characteristic curve.

2. Series diagram

3. Specification and size table of each series of w15 adjustable spiral nozzle Desuperheater

Table twenty-two

| Nnumber |

General schedule |

Mixed pipeline |

Temperature reducing pipe |

H |

L |

Device weight |

|

1 |

W15-001MX |

Φ159×7 |

20 |

144 |

1900 |

258 |

|

2 |

W15-002MX |

32 |

160 |

288 |

||

|

3 |

W15-003MX |

Φ219×9 |

20 |

178 |

2200 |

324 |

|

4 |

W15-004MX |

32 |

185 |

346 |

||

|

5 |

W15-005MX |

Φ273×11 |

20 |

225 |

2400 |

385 |

|

6 |

W15-006MX |

32 |

246 |

415 |

||

|

7 |

W15-007MX |

Φ325×8 |

32 |

302 |

2600 |

416 |

|

8 |

W15-008MX |

50 |

314 949 |

438 |

||

|

9 |

W15-009MX |

Φ377×10 |

32 |

326 |

3000 |

487 |

|

10 |

W15-010MX |

50 |

355 974 |

539 |

||

|

11 |

W15-011MX |

Φ426×11 |

32 |

386 |

3000 |

578 |

|

12 |

W15-012MX |

50 |

402 |

608 |

||

|

13 |

W15-013MX |

Φ530×10 |

32 |

425 |

3500 |

631 |

|

14 |

W15-014MX |

50 |

443 |

665 |

||

|

15 |

W15-015MX |

Φ630×10 |

32 |

480 |

3500 |

690 |

|

16 |

W15-016MX |

50 |

497 |

725 |

||

|

17 |

W15-017MX |

Φ720×10 |

32 |

542 |

3500 |

768 |

|

18 |

W15-018MX |

50 |

568 |

815 |

Temperature reducing device of automatic atomizing umbrella type adjustable nozzle (type w16)

I. working principle:

In the traditional design, the spray part is generally designed as a structure with fixed nozzle flow area. It is only applicable to the condition with basically stable flow. This kind of design can not meet the condition of off design.

Automatic adjustable nozzle is adopted. The section of the water spray is circular structure, the desuperheating water forms a 90 ° umbrella shape, which improves the atomization effect and fully mixes with the steam. When the steam flow rate changes, the nozzle flow area and desuperheating water flow can be synchronized with the required conditions. The desuperheating water has a certain injection speed, which ensures the desuperheating condition when the steam flow changes.

The desuperheating water enters the nozzle directly through the water supply pipe at the inlet of the water inlet flange, and then it will spray out evenly in an umbrella shape after the pressure difference of the water spray head is adjusted. Because the nozzle is designed to be automatically adjustable, the flow rate of the spray flow cross-sectional area is the same, and the spray velocity of the desuperheating water is the same, which achieves a good atomization effect. The desuperheating water after atomization absorbs heat from the steam, heats up, vaporizes and mixes with the steam, thus reducing the steam temperature. The atomization effect is obviously improved.

The working mechanism of the automatic adjustable nozzle: when the steam flow increases, the desuperheating water demand increases, the valve flap of the feed water regulating valve rises, the flow area increases, and the fluid resistance and pressure drop of the regulating valve decrease. As the pressure drop of regulating valve decreases, the pressure drop of nozzle increases, the flow rate of feed water increases, and the flow rate of desuperheating water increases. At the same time, when the pressure drop of the nozzle increases, the force of desuperheating water on the sprinkler head increases, the sprinkler head moves downward, the annular flow area of the nozzle increases, the velocity of the nozzle is constant, and the desuperheating water can be fully atomized.

On the contrary, when the steam flow decreases, the demand of desuperheating water decreases, the valve disc moves down, the flow area decreases, and the pressure drop on the regulating valve rises, the nozzle pressure drop decreases, the feed water flow rate decreases, and the desuperheating water flow decreases. At the same time, when the pressure drop of the nozzle decreases, the force of the desuperheating water on the spray head decreases. Because of the force of the spring, the spray head moves upward, the annular flow area of the nozzle decreases, the flow velocity of the nozzle is constant, and the desuperheating water can be fully atomized to ensure the effect of desuperheating.

II. Structural features:

A. the automatic atomizing umbrella shaped adjustable nozzle, a simple mechanical atomizing temperature reducing device, is a nozzle with variable geometry and back pressure opening.

B. adjust the flow area of the desuperheating water of the nozzle by changing the force of the desuperheating water on the spray head and the spring force, so as to change the desuperheating water quantity and make the desuperheating water fully atomized.

C. by changing the geometry of the nozzle, the adjustable ratio of the desuperheating device can reach 20:1, and under the best condition, it can achieve good atomization at the steam flow rate as low as 5m / s.

D. due to the use of reverse sealing, when the pressure of desuperheating water suddenly decreases, it can be closed quickly, which plays a role of preventing steam backflow.